Calibration

A NIST-traceable calibration provides confidence in the accuracy of measurements as it proves that the instrument has been compared to established measurement reference standards.

Highest calibration standards

To ensure optimal performance for your laser application, it is of the utmost importance that the laser output be measured with a highly accurate measurement instrument.

Almost all Gentec-EO’s measurement instruments come with a NIST-traceable calibration. This guarantees that the measurements taken by the instruments are reliable and accurate.

What is a NIST-traceable calibration?

A NIST-traceable calibration is a calibration process in which the measurement reference standards used are traceable to the National Institute of Standards and Technology (NIST). NIST is a metrology institute responsible for developing and maintaining measurement reference standards in the United States.

This traceability establishes a documented and unbroken chain of measurements to the unit definition as determined by the International System of Units (SI), ensuring that the calibrated instruments or equipment meet the accuracy and precision requirements defined by NIST.

In practical terms, a NIST-traceable calibration provides confidence in the accuracy of measurements, as it aligns with established measurement practices and ensures that the calibrated instruments have been compared to highly accurate measurement reference standards. This traceability is crucial in various industries where reliable and accurate measurements are essential to ensure the performance of laser systems. The result is that a measurement taken at one point in time and space can be reliably compared to another measurement taken at a different time and place.

Benefits of a traceable calibration

Day-to-day, real-life examples of benefits obtained from a traceable calibration include:

- Make valid comparisons of measurements taken by other instruments inside and outside your organization and over time

- Comply with regulations or conform to industry standards

- Avoid costly measurement mistakes in your operations

- Improve customer confidence in your laser systems

- Ensure laboratory experiment validity

- Demonstrate measurement accuracy easily with the calibration certificate we provide

The Gentec-EO advantages

GOLD Calibration Standards

We use only GOLD Calibration Standards, guaranteeing our customers the lowest calibration uncertainty possible.

NIST TRACEABILITY

Our Personnal Wavelength CorrectionTM (PWC) data offers you NIST and/or NRC traceability over the entire range of the detector.

PROVEN STATISTICAL CALCULATION PROCESSES

Our uncertainty values are based on proven statistical calculation processes.

50 PARAMETERS COLLECTED AND LOGGED

For each detector that we calibrate, 50 parameters are collected and logged in our quality system.

CHECKED UP TO 3 TIMES

The calibration reference is checked 2 to 3 times during EACH calibration process.

TOTAL ACCURACY

Each of these steps contributes to the TOTAL ACCURACY of your detector.

The calibration process

By definition, calibration is a comparison between measurements, one of a known magnitude or correctness, which is typically called a “gold standard”, and another measurement comparable to the first one.

In the calibration process, there are four critical aspects that need to be controlled precisely:

1 - Comparison

The first step in the calibration process is the comparison to a known and traceable standard. At Gentec-EO, we always do this using Gold and not a Silver calibration standards, unlike some of our competitors.

This extra carefulness in the comparison process comes from decades of experience in the laser measurement business.

2 - Gold standard

Gentec-EO’s gold laser power detector heads are compared to NIST standard calorimeters at different wavelengths, in accordance to the different lasers used to calibrate your own detector heads. The laser beam has a nominal diameter appropriate for the detector, and is centered on the detector’s absorbing surface.

The laser energy impinging upon the test instrument is measured concurrently using a NIST standard calorimeter and a calibrated beam splitter. The beam splitter ratio is measured using NIST standard calorimeters. Before the measurements are performed, the test instrument is allowed to reach equilibrium with the laboratory environment.

The calibration factor is found by dividing the instrument output reading by the calculated average incident laser power. The calculation is based on the output reading of the NIST standard calorimeters

3 - Uncertainty calculation

At Gentec-EO we offer the best uncertainty on the market, which means more than just giving the customer the lowest uncertainty value. These calculations also need to follow recognized statistical calculation standards, including those given in NIST’s Technical Note 1297.

Another important parameter to verify, and one that is less known, is the confidence level. At Gentec-EO, we use a very high confidence level of 95%. Like every other step in the calibration process, our uncertainty calculations are done rigorously.

We don’t aim to give you just the lowest number, whatever its meaning, we rather aim to give your the true value, with the highest confidence possible.

4 - Certification

Gentec-EO has been using its own control quality system for many years and is now accredited ISO/IEC 17025:2017.

Over and above the quality system certification process, the most important aspect is how rigorously the different steps and parameters are controlled in order to deliver an accurate calibration day after day.

The facts

Electrical instruments

All of our electrical instruments are calibrated by certified calibration suppliers. They certify that, at the time of calibration, the instruments used for calibration meet or exceed all published specifications and have been calibrated using standards whose calibrations are traceable to the NIST and/or other recognized international standards. The electrical and physical properties of their laboratories meet the highest requirements for ambient temperature, relative humidity and cleanliness. Their equipment is maintained by procedures that meet the requirements of ISO 9001:2015 and ISO/IEC 17025:2017.

HOW GENTEC-EO CALIBRATES YOUR DETECTOR

Every detector is individually calibrated to the best possible accuracy traceable to NIST standards. Stable laser sources at various wavelengths are used in our calibration process.

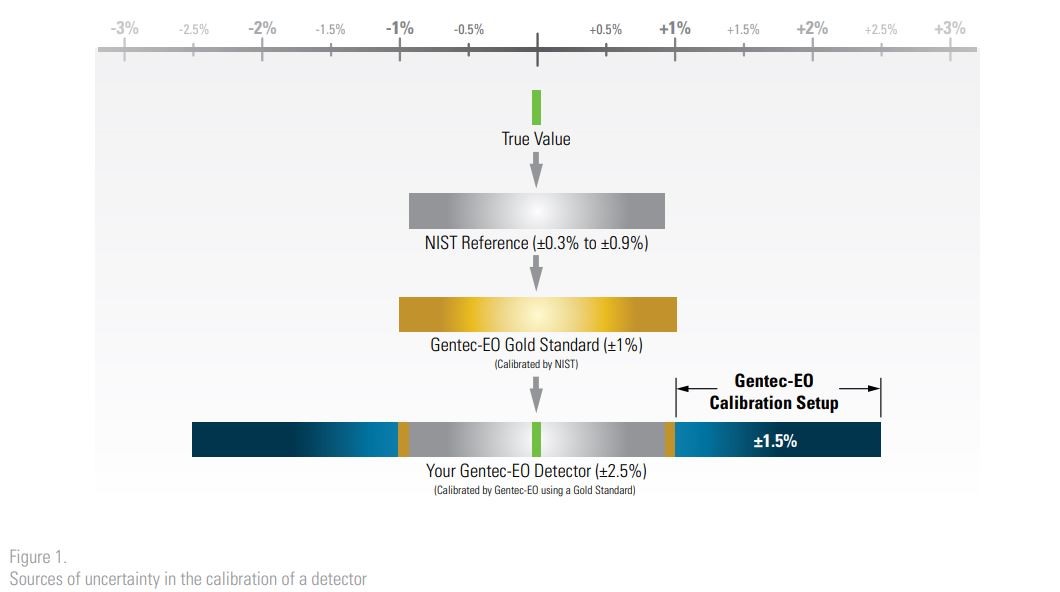

UNCERTAINTY

One very common misconception is the absolute value of calibration uncertainty. Be aware that this value is made using a complex statistical method that takes in account ALL the sources of uncertainty that are present in the process. Figure 1 below shows these steps and their respective contribution to the value of uncertainty. As you can see, the manufacturer itself is only one of these sources.

CALIBRATION WAVELENGTHS

Another misconception is that any wavelength can be NIST calibrated. The NIST only supplies references for distinct wavelengths contained between 157 nm (F2 excimer lasers) and 10.6 μm (CO2 lasers). Every other wavelength within this range or out of this range is subject to an additional error.

For more information about NIST’s calibration wavelengths, please visit their website at: https://www.nist.gov/calibrations

PERSONAL WAVELENGTH CORRECTION CERTIFICATE

To fill the gaps between the NIST references, Gentec-EO offers you the only NIST traceable calibration in nm steps, from 250 nm to 2.5 µm. We achieve this using our proprietary setup that is based on a NIST traceable spectrophotometer. This way, instead of supplying you with typical values, we offer you a NIST traceable calibration. What you get is an overall accuracy that is not more than ±1% away from the original calibration accuracy, in the spectrum of 300 to 2200 nm.

Each Gentec-EO detector comes with a Personal Wavelength Correction Certificate. The correction factors are based on measurements that were made with YOUR detector. They are not based on the general curve of the absorbing material or the general response of equivalent products. This means you get the best wavelength correction tool available on the market. This data is stored in the Smart Interface of your Gentec-EO detector, you just have to select the wavelength in your monitor to get the most precise laser measurements on the market.

The terms

ACCURACY

The accuracy of a measurement is defined as the closeness of the agreement between the result of a measurement and the true value.

REPEATABILITY

The repeatability is the closeness of the agreement between the results of successive measurements under the same conditions of measurements.

UNCERTAINTY

Uncertainty is a measure of the “goodness” of a result. The definition and concept of uncertainty is a quantitative attribute to the final result of measurement, considering all systematic and random components of all known input quantities.

REPRODUCIBILITY

The reproducibility is the closeness of the agreement between the results of successive measurements under changed conditions of measurements. This is also defined as “precision under reproducibility conditions”.

PRECISION

The precision of a measurement is defined as the closeness of agreement between independent test results obtained under stipulated conditions.

ERROR

The error on a measurement is the difference between the measurement result and the true value.

Find a calibrated laser power or energy detector

Let us guide you in selecting the best laser power or energy detector for your application. You only need to answer 3 simple questions about your laser.